How to Choose A CNC Precision Machining Factory in China?

With the changes in the international situation and the continued confrontation in the Sino-US trade war, it is a serious blow to China's manufacturing industry! We all know that many orders go to countries such as Vietnam or Mexico. However, we cannot ignore the power of China's manufacturing industry, especially in the CNC precision manufacturing industry, which requires high upstream and downstream supply chain requirements and requires relatively high-quality and low-cost operating and technical employees. This is something that other countries cannot Alternative to China!

However, there are so many CNC precision machining factories in China. How to choose a more suitable CNC precision machining factory in China has become a topic of interest to many people!

In fact, it is very easy to choose a suitable CNC precision machining factory in China. There are six main points that must be paid attention to:

1. Definitely the price, because the price factor determines whether it is in line with the company's purchasing plan and expectations.

2. The delivery capability of the factory, because if a factory's quotation is competitive, but they are unable to deliver on time, as far as procurement is concerned, it is also a headache if they cannot deliver on time.

3. The company's equipment technology level. It has more advanced CNC processing equipment and technology, which can provide more high-precision and fast processing services for product manufacturing!

4. You need to pay attention to the factory's operating history, processing experience and some professional capabilities, such as whether it has ISO certification.

5. Service attitude. A factory with good service attitude and smooth communication can improve your work efficiency a lot, and can also provide you with some professional suggestions for your inquiries when necessary!

6. The quality control system and process of this factory, which ensures that every part produced meets the requirements and has a long-term quality guarantee!

Next, we will discuss these six points in detail!

What kind of quotation is cheap, and what are the key factors in the quotation?

First of all, we need to know that there is no lowest quotation in China, because there will always be a lower quotation for you! Due to various factors in the market, CNC processing factories in China are under considerable competitive pressure. The strategy of attracting customers at low prices has been adopted by many factories! However, low prices cannot last forever and may eventually become more expensive in another form. Therefore, understanding the key factors of quotation and factories that can provide quotation analysis are more reliable! Regarding several major factors in quotation, you can move to my other blog to learn more!

How does a CNC machining factory ensure delivery time?

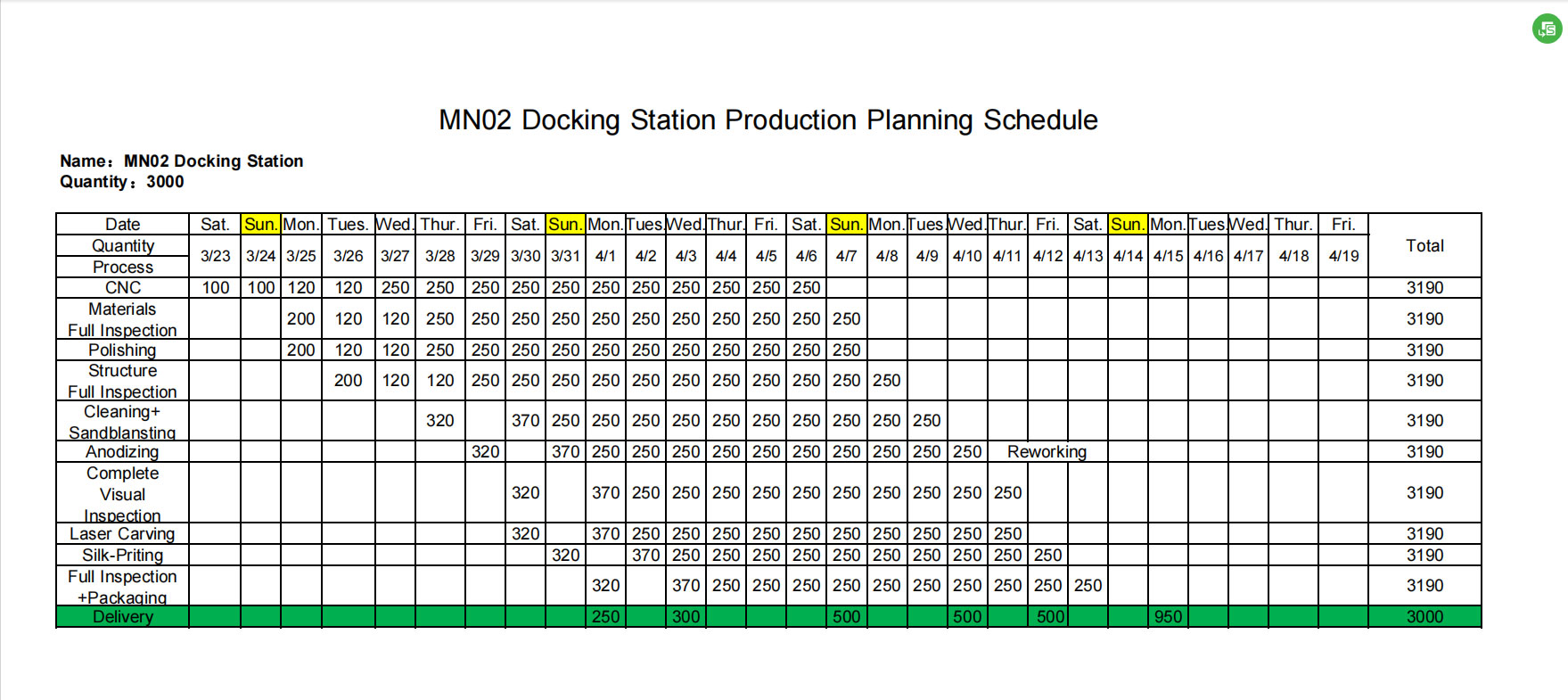

Delivery time is an important factor in any trading relationship, and we at JXGC are well aware that there are many aspects involved in delivering on time. Generally speaking, our JXGC sample delivery time is 15 days. For large quantities, the delivery time is determined based on the quantity of the goods. Generally speaking, the delivery time for less than 5,000 pieces is 30 days.

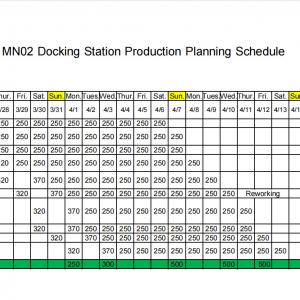

We will arrange the production plan reasonably for each order. After the project is confirmed, our factory director will schedule the production progress at the morning meeting and formulate a detailed production plan schedule to give to our customers.

After each of our order projects is established, a professional project manager will carefully follow the order, report the order progress at any time, discover problems in a timely manner, and take corresponding measures to ensure that there is no delay in the production process.

We maintain close contact with raw material manufacturers, profile mold suppliers or process processing partners. Based on our long-term and stable cooperation and professional communication, we can effectively carry out supply chain management to ensure delivery.

What equipment and technology levels should a CNC factory have?

Our JXGC is a factory with more than ten years of experience in supplying metal casings and components for smart devices. We have advanced CNC processing equipment, including 3-axis, 4-axis, and 5-axis CNC machines, and we perform regular equipment maintenance and repairs. Ensure the accuracy requirements of processed products and the stability of batches!

Regarding drawings, the drawing files we accept include 2D CAD format files, 3D STEP, and SW format files. Regarding process paths or tool paths, we often use CAM to guide CNC machine tool processing.

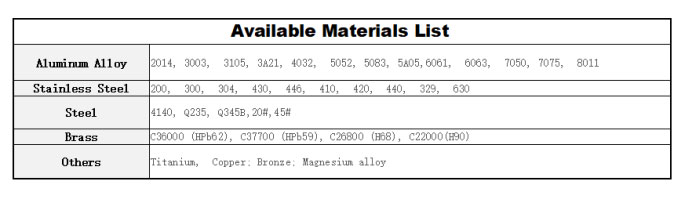

The materials we process are mainly aviation-grade aluminum alloy 7075, but we also accept materials of different hardnesses such as stainless steel, copper, and titanium alloys. The following picture is our common processing metal table:

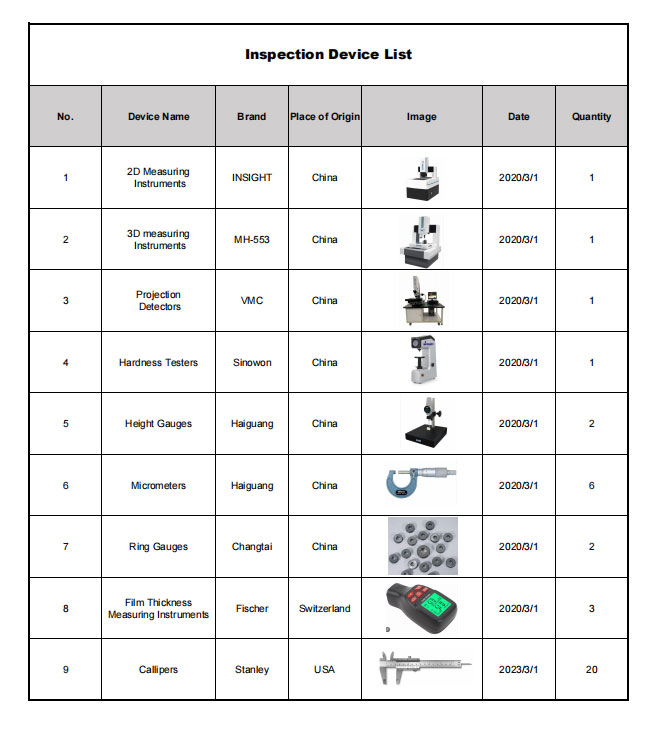

Regarding quality testing equipment, our company has a dedicated testing equipment room. The testing equipment includes 2D measuring instruments, 3D measuring instruments, projection detectors, hardness testers, height gauges, micrometers, ring gauges, film thickness measuring instruments, wear meters, etc. The following is our testing equipment table:

How to check whether the quality control system and process of a CNC processing factory are complete?

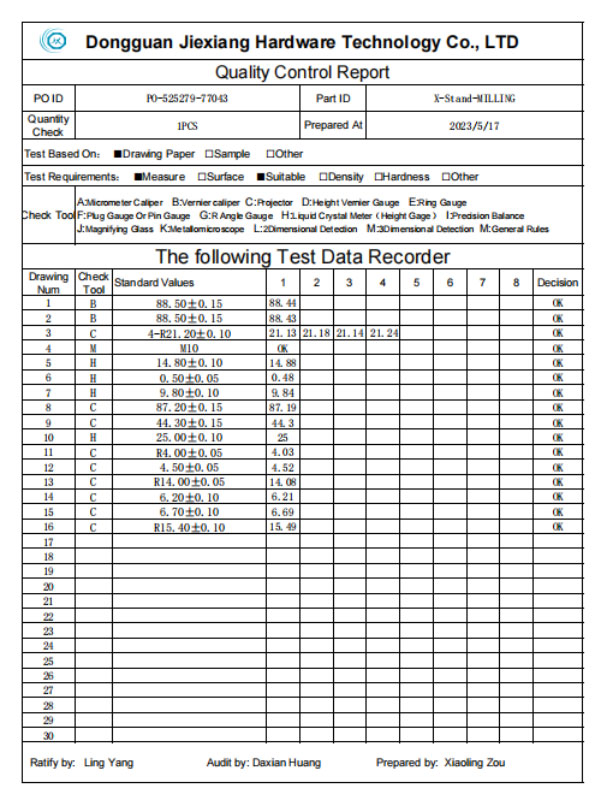

First of all, before visiting the factory, we can ask the factory to provide relevant state-issued quality management systems. If there is no way to provide even the ISO9001 certification, then the quality of this company must not be up to standard. Then ask how the quality control process is controlled, communicate with the quality department manager, understand the quality management process, and take a look at how this CNC processing factory inspects raw materials, processing processes and final products, and whether the entire inspection process is reasonable. During this inquiry process, you can learn how the testing equipment is used in the testing process, and see how the testing reports and process flow cards are circulated in the process. Finally, ask clearly about the quality complaint process and after-sales service policy, so that you can have a reasonable acceptance plan when you encounter quality problems later! After the inquiry, you can visit the factory to see if the overall situation of the production workshop is true.

How to judge whether a CNC manufacturing factory has production experience and professional capabilities?

First of all, an important basis for judgment is to understand when the company was established. Generally speaking, the longer it has been established, the more experienced it will be. Another is to see if there are similar industry product cases. Each company focuses on different product areas. Some focus on internal parts, and some focus on appearance parts. JXGC focuses on the appearance parts of smart products. For this reason, we have a good grasp of the appearance of smart products, such as laptops, smart wearables, projectors, keyboards, handheld consoles, smart locks, HIFI and diving robot products. Has rich production experience. Another one is that we have experience in serving big brand customers such as Huawei, FIIO, GPD, SONY and so on. Furthermore, our workforce is a young and dreamy team. We have a complete internal management system and a standardized training system. We respond quickly and agilely to customer needs. This is the reason why major customers choose us!