Product Schedule in CNC Precision Machining

In the field of CNC precision machining, product schedules play a vital role. For CNC precision machining manufacturing companies, it is not only the cornerstone of production planning, but also the key to production efficiency and quality control.

Effect

CNC product schedule plays an important role in the manufacturing industry. The five functions are discussed below:

1. Production planning and arrangement

CNC product schedule is the basis for formulating production plans. By reasonably arranging production sequence, processing technology and time nodes, we at JXGC can effectively organize production activities, improve production efficiency, ensure order production is completed on time, and then provide our customers with high quality and punctual and effective service

2.Optimization of production resources

JXGC generally develops the schedule by our factory director Zhou. He has rich experience in scheduling plan management. He can reasonably plan and dispatch production factors such as production equipment, human resources and raw materials, and implement it in the actual production process. Optimize the allocation of production resources to maximize equipment utilization and manpower efficiency, reduce production costs and improve production efficiency for all our JXGC customers.

3. Delivery time control

Once a schedule is completed, it can clearly stipulate the time node and completion deadline of each production link, helping each of our JXGC employees and each key link to grasp the order delivery time and predict possible delays in advance. And promptly reminded us, Factory Manager Zhou, to take adjustment measures if necessary to ensure that orders are delivered to customers on time, thereby improving our customer satisfaction.

4.Production progress monitoring

The schedule is an important tool for monitoring production progress and production efficiency. Director Zhou can keep abreast of the actual completion of each production link through the schedule, identify problems at key nodes at any time and take measures to solve them, ensuring that every product can be completed smoothly. Delivery on time.

5. Improve production quality

With a reasonable schedule plan, we can avoid workers from being in a hurry during the production process due to poor timing. Only when employees know the priorities of events and projects can they concentrate on production and improve processing accuracy and quality stability. safety to ensure product quality meets requirements.

CNC product schedules play an important role and significance in the manufacturing industry. They can help enterprises reasonably arrange production plans, optimize resource allocation, control delivery time, monitor production progress and improve production quality, thereby enhancing the competitiveness and operating efficiency of enterprises.

Scheduling Basis

About us Factory Director Zhou’s formulation of the CNC product process schedule is the result of comprehensive considerations, including the urgency of customer needs and other factors. However, the main basis is the following four aspects:

1. Order requirements

First of all, Director Zhou will clarify the needs and delivery time of customer orders with each salesperson at the daily morning meeting before making the production schedule. Develop corresponding production plans and schedules based on the order quantity, product type, delivery time and other requirements placed by the customer. Order requirements are the basis for making process schedules, and production plans need to be arranged according to customer needs.

2. Equipment status

The prerequisite for making a schedule is to have an understanding of the status of our JXGC production equipment. We should be able to memorize the long-term processing experience and efficiency of our projects as well as the daily production capacity of the machine. The availability, performance, maintenance status, etc. of CNC processing equipment will affect the production progress, so the data will be updated in time every period of time. Arrange the production plan according to the actual situation of the equipment, so as to ensure that the equipment can operate normally and meet production needs.

3. Process flow

The schedule also needs to consider the specific processing process of the product. Different products may need to go through different processing steps and processes. Some are more complex and may need to be matched with multiple machines or multiple processes. This requires arranging production plans according to specific process requirements to ensure that each product All processing steps are completed on time.

4.Human resources

The most important thing in the schedule is to take into account the human resources situation on the production line. Staffing, technical level, etc. will all affect production efficiency and progress. Therefore, personnel scheduling and cooperation will affect product delivery. If necessary, whether it is necessary to arrange support and assistance from other departments to ensure the smooth progress of the production plan needs to be carefully considered!

Taking the above factors into consideration, the process schedule can be formulated based on factors such as order requirements, equipment status, process flow, and human resources to ensure the rationality and smooth implementation of the production plan.

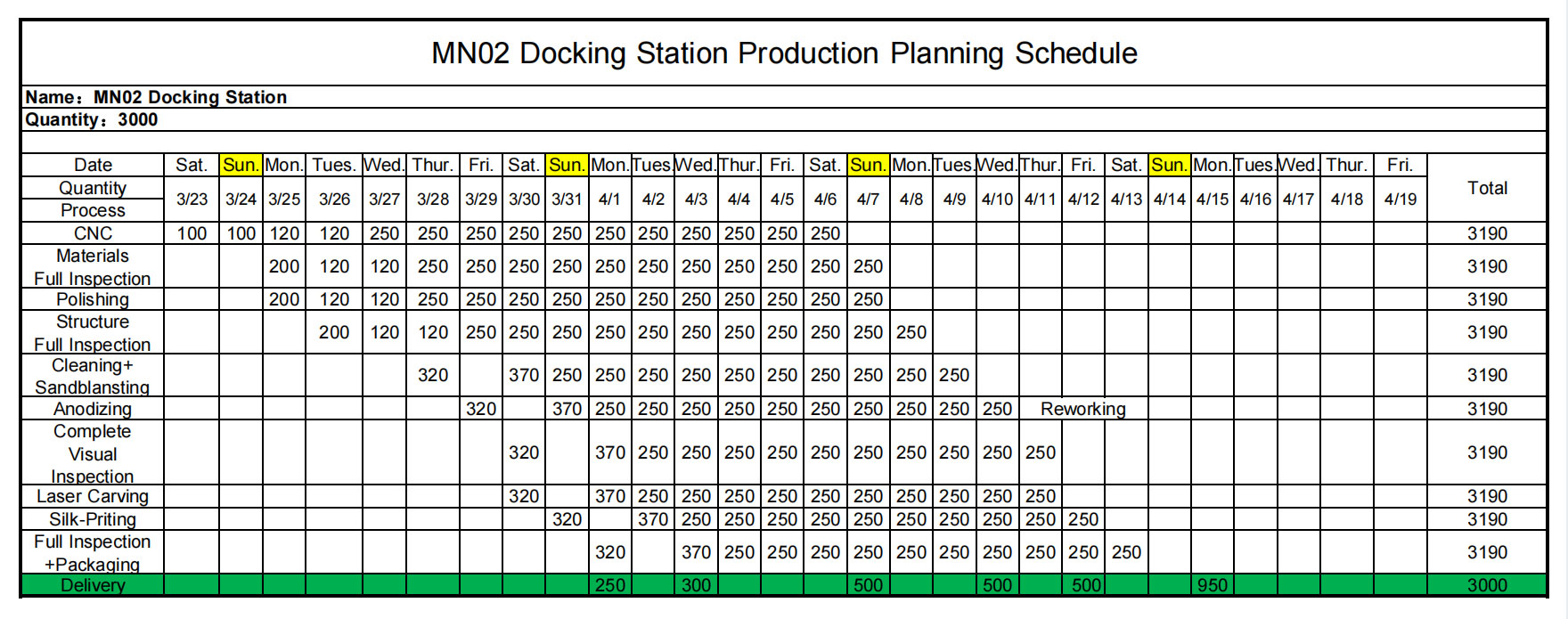

Schedule Example

Specific cases are used to demonstrate the formulation and implementation of the schedule, including order receiving, production plan formulation, production resource scheduling, production monitoring and adjustment, etc., and the application and effect of the schedule in actual production are explained.

Through in-depth understanding and scientific application of CNC product schedules, manufacturing companies can improve production efficiency, optimize resource allocation, enhance market competitiveness, and achieve sustainable development.

The following is a schedule for a docking station product ordered by our customer for your reference: