Description

MUSIC SERVER CHASSIS

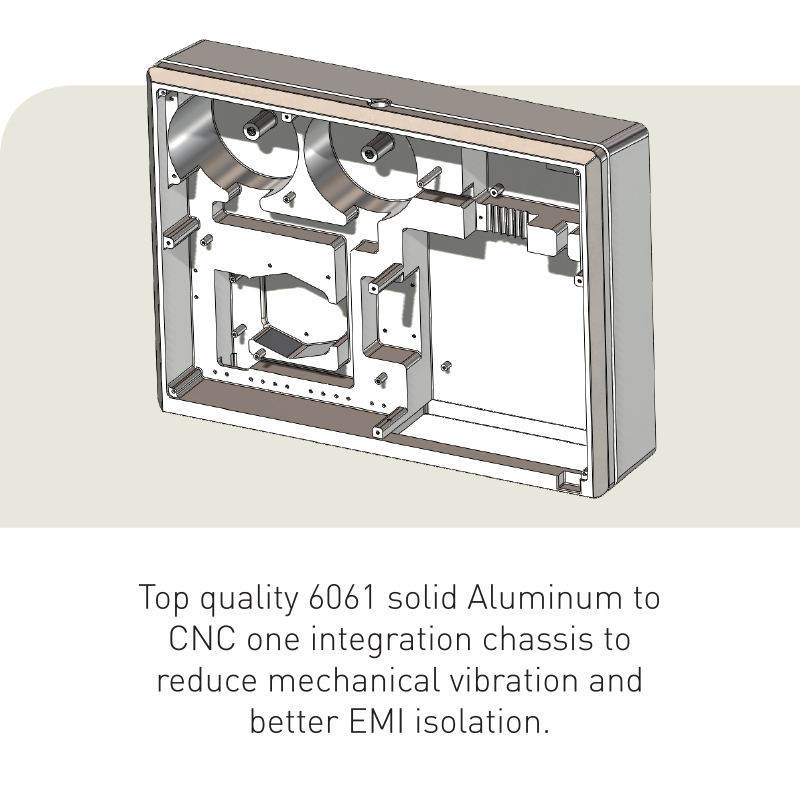

This is an aluminum alloy 6061 CNC precision machined music servo machine case. It weighs up to 20kg.

It is somewhat challenging in terms of processing difficulty.

The 180# zirconium sandblasting process makes the surface more comfortable to the touch. It is anodized in silver color to see the luster and elegance of the metal itself.

What needs special attention is that during the processing of this chassis, due to its large size, the processing is very difficult. For this reason, our team needs to overcome many difficulties. Especially when larger volumes enter the anodizing tank, special attention needs to be paid to avoid unnecessary scratches or falls caused by bumping into the product during the process!

There are many design styles of our music servo machines. They are used in on-site layout scenes in large concert venues. At the same time, they are placed on balconies at home, which tests the texture of the metal surface. Sometimes the scattered light under the setting sun will be directly reflected Check whether the finest sandblasting texture on the metal surface is even.

The aluminum alloy 6061 of our metallic music servo machine chassis is customized according to customer requirements. The customer provided us with a complete set of 3D SPET documents and 2D DWG document formats of each component indicating the inspection standards and data inspection items, so as to serve as the basis for quality inspection.

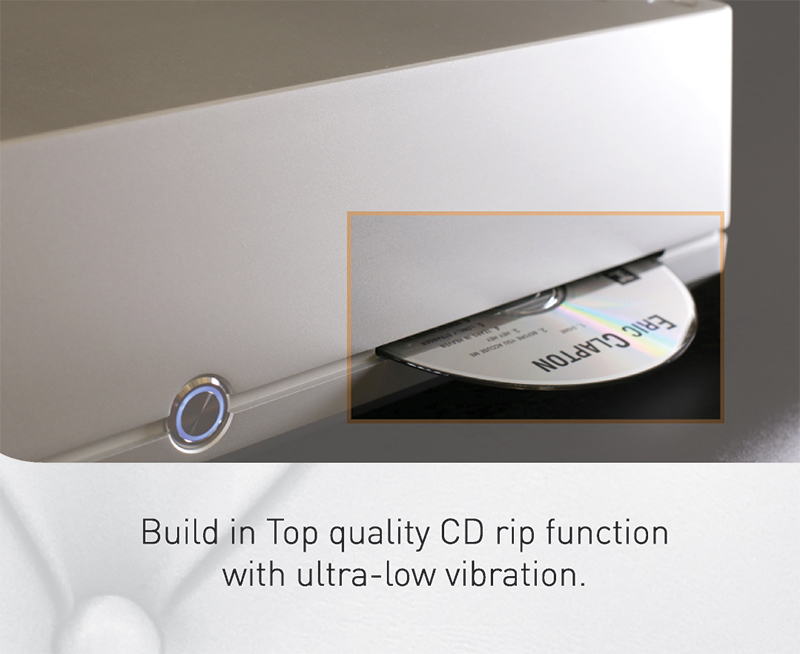

For the power-on button and the CD rip import card slot located in the front of the chassis, we use a small reamer to proceed to the finishing step after CNC rough machining. This 5.1mm wide piece needs to be connected on all three sides, which also requires a certain degree of difficulty.

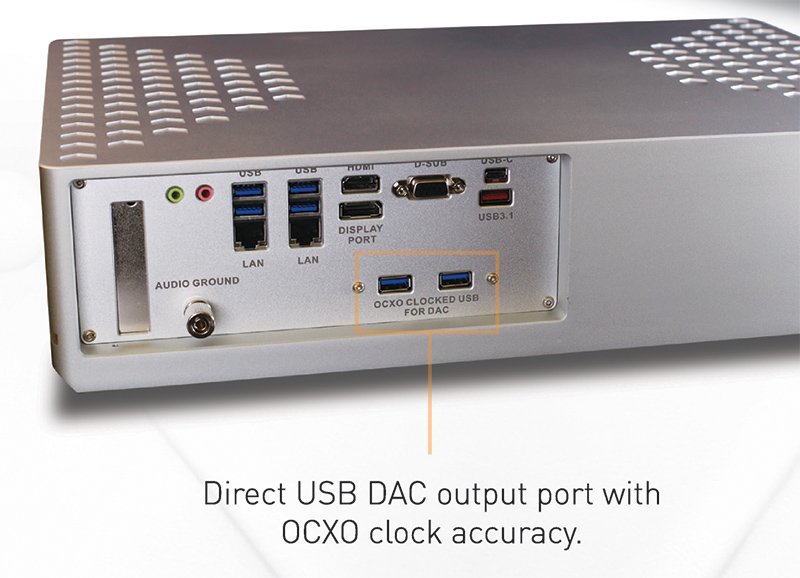

The text on the back of the chassis is used to control USB or power inlet and outlet jacks. We use laser engraving. Customers can also choose a multi-language version for laser-engraved text.