Both types of anodizing (hard anodizing and normal anodizing) are common surface treatment techniques and each has advantages and disadvantages.

Advantages of hard oxidation:

1.Strong wear resistance: The ceramic film formed by hard oxidation has excellent hardness and wear resistance, which can effectively protect the surface of the material and prolong the service life.

2.Good corrosion resistance: hard oxidation can form a dense oxide layer, improve the corrosion resistance of the material, and block the erosion of external corrosive media.

3.Excellent insulation performance: the hard oxide film has good insulation performance and can be used in electronic devices, electrical insulation and other fields.

4.High surface hardness: Hard oxidation makes the surface of the material have higher hardness, providing better scratch resistance and wear resistance.

Disadvantages of hard oxidation:

1..Complex process: hard oxidation requires strict preparation conditions and control, the process is relatively complex, and may have high requirements for equipment and processes.

2.Higher cost: Compared with ordinary oxidation, the cost of hard oxidation is higher, including equipment investment, energy consumption and processing time.

Advantages of ordinary oxidation:

1..Low cost: Compared with hard oxidation, the cost of ordinary oxidation is lower, which is suitable for large-scale applications.

2.Simple operation: the ordinary oxidation process is relatively simple, easy to implement and control.

3.Strong processing adaptability: ordinary oxidation can be applied to materials of various shapes and sizes, and has good adaptability.

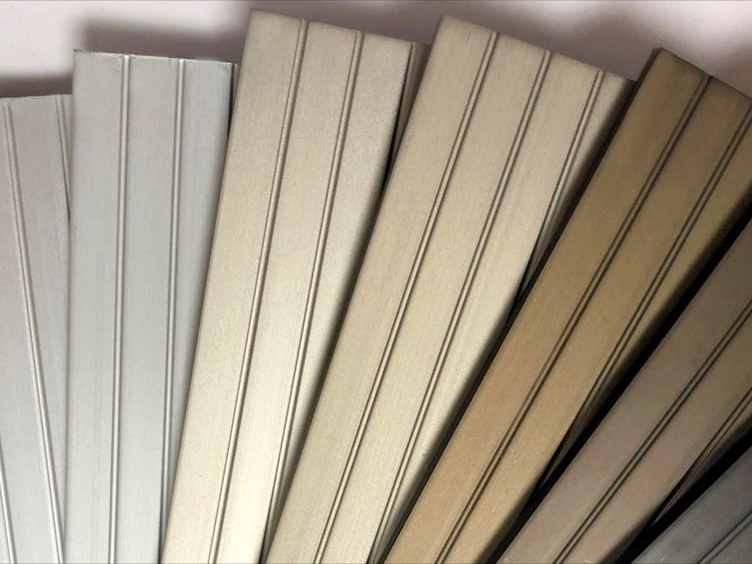

4.Can improve the surface texture: Ordinary oxidation treatment can improve the appearance texture of the material, making it have a better look and feel and decorative effect.

Disadvantages of ordinary oxidation:

1.Poor wear resistance: The oxide layer formed by ordinary oxidation is relatively thin and has poor wear resistance, which may not be ideal for high-demand wear resistance scenarios.

2.Poor corrosion resistance: The ordinary oxide layer is relatively thin and has limited resistance to corrosive media.

In summary, hard oxidation has advantages in terms of wear resistance, corrosion resistance, insulation and surface hardness, but the cost is high and the process is complicated; while ordinary oxidation has the advantages of low cost, simple operation and strong processing adaptability. Advantages, but relatively poor wear resistance and corrosion resistance. Which anodizing technology to choose should be weighed according to specific needs and considerations.